Dec. 08, 2025

Multi-ply conveyor belts are among the most widely used belt types in bulk material handling and general industrial conveying. Their layered fabric construction provides a balance of strength, flexibility, and cost efficiency, making them a reliable choice across many industries.

However, choosing the right multi-ply conveyor belt often raises practical questions. Understanding these questions—and their answers—helps buyers avoid premature wear, downtime, and unnecessary replacement costs.

Below are the five questions most commonly asked when evaluating multi-ply conveyor belts.

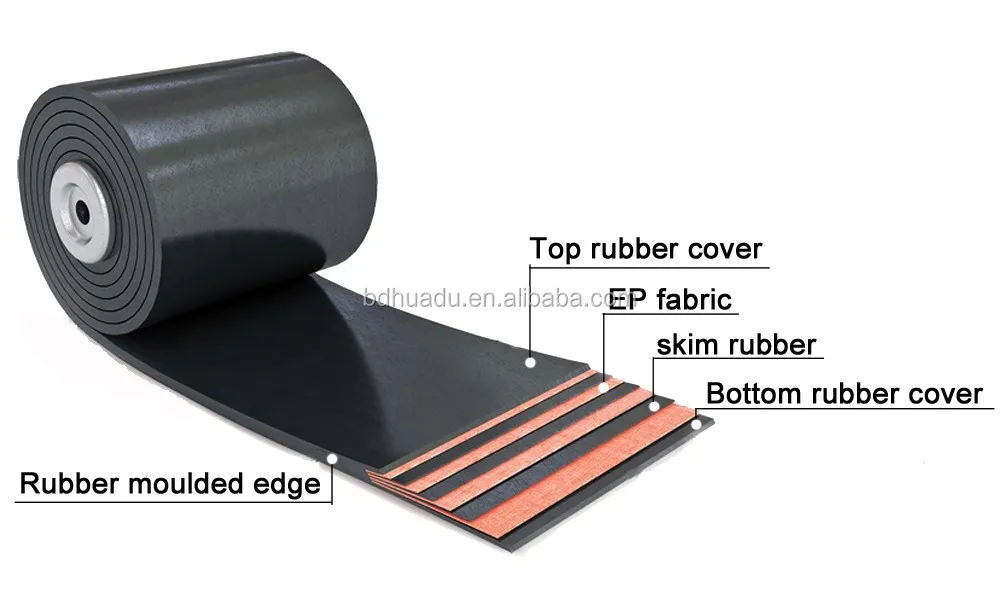

A multi-ply conveyor belt is constructed from multiple layers (plies) of fabric reinforcement bonded together with rubber. Each ply adds tensile strength and load-carrying capability.

Typical fabric materials include:

Polyester

Nylon (polyamide)

Cotton or blended fabrics

The plies are sandwiched between a top cover rubber (for load protection) and a bottom cover rubber (for pulley contact and wear resistance).

The number of plies—commonly ranging from 2 to 6 or more—is selected based on required strength, impact resistance, and operating conditions.

This is one of the most common comparison questions.

The key difference lies in reinforcement structure:

Multi-ply belts use fabric layers for tensile strength.

Steel cord belts use high-tensile steel cords.

As a result:

Multi-ply belts offer better flexibility and are easier to install and splice.

Steel cord belts provide significantly higher tensile strength and are better for very long-distance or extremely heavy-duty applications.

Multi-ply conveyor belts are typically preferred for short-to-medium distances, moderate loads, and systems requiring tighter pulley diameters.

The required number of plies depends on several factors, not just load weight.

Key considerations include:

Material weight and bulk density

Impact at loading points

Belt width and speed

Conveyor length and incline

Pulley diameter and system design

Using too few plies can result in stretching, tearing, or premature failure. Using too many plies may increase cost and reduce belt flexibility.

Proper belt selection balances strength and flexibility to match the conveyor system’s actual operating conditions.

Multi-ply conveyor belts are highly durable when properly specified, but performance depends largely on the rubber cover compounds and construction quality.

They can be engineered for:

Abrasion resistance (aggregates, sand, ores)

Heat resistance (hot materials)

Oil and chemical resistance

Flame retardancy

However, in extremely high-tension, long-distance, or high-impact environments, steel cord belts may offer longer service life. Multi-ply belts remain the preferred solution where flexibility, impact absorption, and ease of maintenance are critical.

From a total cost perspective, multi-ply conveyor belts are often one of the most cost-effective options available.

Advantages include:

Lower initial purchase cost than steel cord belts

Easier splicing and repairs

Reduced downtime due to simpler maintenance

Compatibility with a wide range of conveyor systems

For many industries, the balance of price, performance, and availability makes multi-ply conveyor belts the most practical choice for continuous operation.

Multi-ply conveyor belts remain a cornerstone of material handling systems worldwide. Their layered fabric structure delivers reliable strength, flexibility, and durability across a wide range of applications.

By understanding what multi-ply belts are, how they differ from other belt types, how many plies are required, and where they perform best, buyers can make informed decisions that reduce operating risk and extend equipment life.

When properly selected and manufactured, multi-ply conveyor belts offer dependable performance and long-term value for industrial conveying applications.

32

0

0

All Comments (0)

Previous: How Underwater Rotary Actuators Enhance Marine Operations

Next: Exploring Underwater Rotary Actuators: Innovations & Applications

If you are interested in sending in a Guest Blogger Submission,welcome to write for us!

Comments